Country

Year

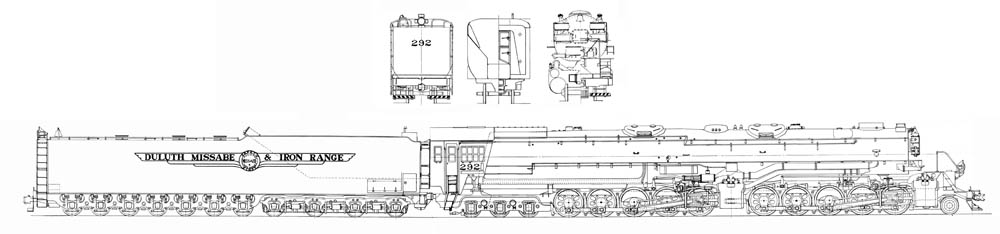

Class

Superheated steam 4 cylinder single esp.

2-10-10-6

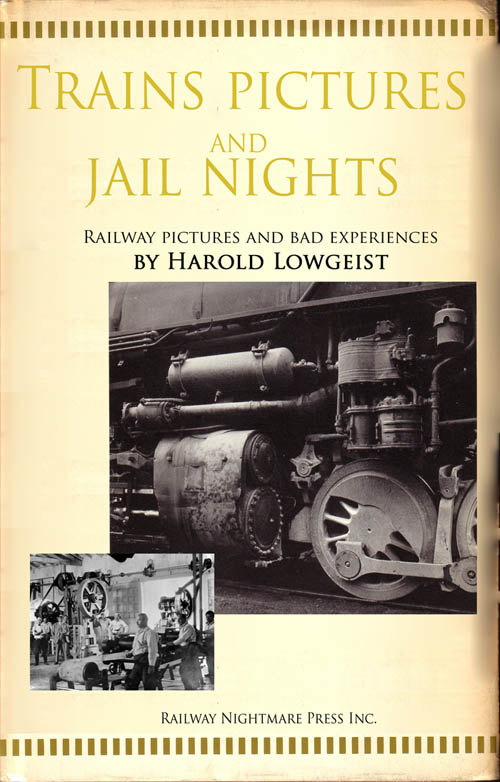

Among the U.S. companies sick with gigantism is surely the Duluth, Missabe & Iron Range. This company handled the traffic of iron ore between the mines of the Middle West and the ports on the Great Lakes. These lines were not particularly steep, but their sawtooth profile often made pushing necessary for short stretches. DMIR brilliantly solved its traffic problems with the stunning M4-class Yellowstones. They were capable of pulling endless convoys of ore-laden hoppers over the entire route. The outbreak of World War II and the increased demand for ore on the East Coast began to require the dual traction use of these machines, with a significant increase in operating costs. DMIR therefore asked ALCO to further develop the design and this M-6, named Ironclad, was born. With a monster furnace and a steam output above suspicion, this machine, numbered 292, eliminated the problem at the root. The two coupled 5-axle trains that had already made Virginian's 900s famous, combined with a 6-axle rear carrier, allowed the machine to haul 30% more ore without requiring additional personnel. In fact, there was one problem: the enormous, insatiable appetite for coal (fortunately for the stoker, an efficient and modern stoker had been installed) and water. The tender, the largest ever built for a steam locomotive, had big problems in entering curves and lent itself to derailment in the changes of slope typical of DMIR lines. Put into service at the beginning of 1940, the machine was used on the straightest route available, between Ironsourge and Decharge on Lake Superior, but the frequent derailments of the tender made it problematic to continue the experiment. Therefore alternative solutions were tested and the car was equipped with the Centipede tender of the M-4 class, whose capacity, however, did not allow to overcome the entire stretch without refueling. It was therefore decided to postpone the construction of the planned series of 10 machines and the prototype remained a unique specimen until moving endless rows of wagons in the port of Duluth. The running costs convinced the DMIR managers to shelve the machine in 1946 and to proceed almost immediately to its demolition.

Among the U.S. companies sick with gigantism is surely the Duluth, Missabe & Iron Range. This company handled the traffic of iron ore between the mines of the Middle West and the ports on the Great Lakes. These lines were not particularly steep, but their sawtooth profile often made pushing necessary for short stretches. DMIR brilliantly solved its traffic problems with the stunning M4-class Yellowstones. They were capable of pulling endless convoys of ore-laden hoppers over the entire route. The outbreak of World War II and the increased demand for ore on the East Coast began to require the dual traction use of these machines, with a significant increase in operating costs. DMIR therefore asked ALCO to further develop the design and this M-6, named Ironclad, was born. With a monster furnace and a steam output above suspicion, this machine, numbered 292, eliminated the problem at the root. The two coupled 5-axle trains that had already made Virginian's 900s famous, combined with a 6-axle rear carrier, allowed the machine to haul 30% more ore without requiring additional personnel. In fact, there was one problem: the enormous, insatiable appetite for coal (fortunately for the stoker, an efficient and modern stoker had been installed) and water. The tender, the largest ever built for a steam locomotive, had big problems in entering curves and lent itself to derailment in the changes of slope typical of DMIR lines. Put into service at the beginning of 1940, the machine was used on the straightest route available, between Ironsourge and Decharge on Lake Superior, but the frequent derailments of the tender made it problematic to continue the experiment. Therefore alternative solutions were tested and the car was equipped with the Centipede tender of the M-4 class, whose capacity, however, did not allow to overcome the entire stretch without refueling. It was therefore decided to postpone the construction of the planned series of 10 machines and the prototype remained a unique specimen until moving endless rows of wagons in the port of Duluth. The running costs convinced the DMIR managers to shelve the machine in 1946 and to proceed almost immediately to its demolition. *** Translated with www.DeepL.com/Translator (free version) ***